New Release : Aerodymatic technology Steam Effects

2022-05-10

Steam effect systems are widely used in entertainment industry. It can create smoke, fog, cloud and even realistic simulated fire to construct a specific sense of atmosphere in live theaters, amusement and theme parks, art exhibits, film set and similar venues.

A conventional steam effect system typically requires continuous supply of steam generated by a steam boiler at around 90 psig pressure and 331 degF temperature, and it relies on the potential energy of high-pressure steam for projection of steam effects. Due to the high pressures and temperatures, the operation and maintenance of the system need to be performed by licensed workers and periodic review of the equipment is required by national designated agency according to the local regulations.

ITMation’s patented Aerodymatic™ technology offers a disruptive way to produce steam effect with greater efficiency, safer and easier to maintain. It redefines the end users’ experience while maintaining responsible, sustainable delivery methods that provide cost-benefits to the customer.

Aerodymatic™ technology utilizes aerodynamic principles in using air or other compressible gases to provide motive energy to eject steam at atmospheric pressure and use the resultant kinetic energy of the combined mass flow to draw in additional atmospheric air to expand the volume of gas to be discharged for the special effects. Meanwhile, it uses the potential energy of compressed air/gas that can be stored indefinitely inside a pressure vessel without any additional energy to maintain. Besides, it allows for close contact with the special effects without the hazards of high temperature steam or real flame, which create the same appeal while maintaining a safe environment for the audience.

Compared to a conventional steam effect system, ITMation’s patented Aerodymatic™ technology offers the following BENEFITS:

1. Over 75% saving on steam generation and keep warm energy.

2. Steam is generated at an atmospheric pressure (0 psig vs 90 psig) and much lower temperature (212 degF vs 331 degF); hence the steam generators, piping/ducting, and steam containers (if required) are not subjected to ASME BPVC and is much safer to operate and maintain compared to a high-pressure steam system.

3. Very low quantity of condensate being generated during operation that can be drained off directly or returned to the water heater for re-boiling without a sophisticated pumping system.

4. 70% less heat and moisture released to the indoor environment.

5. Better visual effects due to higher opacity steam plumes.

6. Quiet and fast response, with negligible response time delays.

7. Easy and low maintenance cost of the equipment.

Below is a demonstration of the steam effects created by the Aerodymatic™ system:

Below shows the Aerodymatic™ nozzle in action producing steam effects in an outdoor show set:

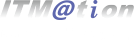

Below is a demonstration of the simulated flame effects created by the Aerodymatic™ system:

Uses of Steam: (Here are some suggestions for places to consider the use of steam)

- Live theater, amusement and theme parks, art exhibits, concerts, film set, cruise ships, etc.- Any indoor venue that plans to use simulated fire instead of real fire due to safety concern.

- Simulate volcanic eruption or support an explosion

- Steam curtains to walk through or pass through in a vehicle

- ……